Defect Elimination

The core objective of Six Sigma, defect elimination by reducing process variation leading to improved product & service quality.

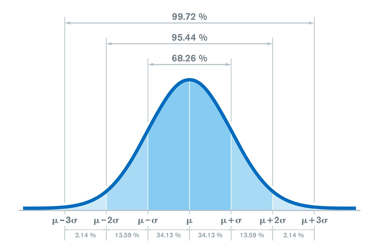

Dating back to the late 18th century when mathematicians first introduced the 'normal curve,' Six Sigma has been an effective method of fine-tuning the measurement of process improvement. 'Sigma,' meaning a standard deviation from the goal of the process, is a way of measuring defects in mathematical formulas, and more recently, business processes. This sounds complicated - it doesn't have to be!!

In the 1920s, business leaders found that three sigma from the mean is the point where a process requires correction. As businesses grew in scale, the toleration for standard deviation grew to six sigma. In the 1980s, Motorola implemented the Six Sigma methodology which in turn saved them $16 billion dollars and brought the idea to light for tens of thousands of companies.

The core objective of Six Sigma, defect elimination by reducing process variation leading to improved product & service quality.

Streamlining processes through Six Sigma eliminates wasted time, effort, and resources translating to increased operational efficiency.

The structured approach and emphasis on data-driven decision making encourage teams to constantly analyze, measure, and refine processes.

Today, Six Sigma is improving businesses all over the world. Companies like Honeywell and General Electric have been touting the benefits of Six Sigma almost 30 years, and other organizations like Amazon, Bank of America, and the United States Army and Marine Corps have implemented Six Sigma with great success.

Implementation of Six Sigma methodology has helped companies improve product quality, delivery, and overall performance. Financial gains, increased customer satisfaction, increased productivity, process variability reduction, and waste reduction are some of the reasons Six Sigma has been so positive.

Achieving stable and predictable process results is the focus of Six Sigma methodology. Six Sigma aims at analyzing definable, measurable, improvable, and controllable processes, similar to The DMAIC Way that has stemmed from this idea. The emphasis on leadership and supporting roles makes Six Sigma a powerful way to delegate tasks to team members trained in their roles.

Six Sigma's belt system trains team members on the various aspects of a project, like data collection and analysis, reviewing project processes, and managing project roles. A strong understanding of Six Sigma philosophies and principles helps businesses handle projects and perform at their best.

Jan 27, 2026 by Scott Burgmeyer

Nov 29, 2025 by BecomeMore Group Staff

Nov 15, 2025 by BecomeMore Group Staff